Ford Has a Major Problem: ‘None of the Young People Want to Work Here’

Ford CEO Jim Farley heard a harsh truth when he spoke to veteran employees during union contract negotiations: young workers were staying away from the company because of low pay. “The older workers who’d been at the company said, ‘None of the young people want to work here. Jim, you pay $17 an hour, and they are so stressed,” Farley said at the Aspen Ideas Festival. Some young Ford employees were juggling multiple jobs, including shifts at Amazon, to survive financially.

Young Workers Were Sleeping Just Three or Four Hours a Night

Farley learned some workers held jobs at Amazon, clocking eight-hour shifts before coming in for seven hours at Ford, leaving them with only three or four hours of sleep. At a Ford Pro Accelerate event in September, entry-level factory workers told the CEO they were juggling up to three jobs. The reality prompted Farley to look back to founder Henry Ford’s historic wage decision more than a century earlier for inspiration.

Henry Ford Doubled Factory Wages to $5 a Day in 1914

Some economists credit Henry Ford with jump-starting the American middle class when, in January 1914, he raised factory wages to $5, more than double the average for an eight-hour workday. Ford’s decision was designed to attract a stable workforce and provide stimulus for workers to afford Ford products. “He said, ‘I’m doing this because I want my factory worker to buy my cars. If they make enough money, they’ll buy my own product,” Farley explained at the festival. “It’s a self-fulfilling prophecy, in a way.”

Ford Made Temporary Workers Into Full-Time Employees

Following the founder’s example, the company converted temporary workers into full-time employees, making them eligible for higher wages, profit-sharing checks, and better health care coverage. The transition was outlined in the 2019 contract negotiations with the United Auto Workers, with temporary workers able to become full-time after two years of continuous employment at Ford. “It wasn’t easy to do,” Farley said. “It was expensive. But I think that’s the kind of changes we need to make in our country.”

The Company Has 5,000 Open Mechanic Positions It Can’t Fill

Farley has sounded the alarm on the shortage of manual laborers. Earlier this month, he said in an episode of the Office Hours: Business Edition podcast that Ford had 5,000 open mechanic positions that remain unfilled, despite salaries reaching up to $120,000 for the role. The unfilled positions highlight a broader crisis in American manufacturing, where younger workers are increasingly avoiding factory careers despite growing demand for skilled trades.

Gen Z Is Largely Eschewing Factory Jobs Due to Low Wages

Despite projections of 3.8 million new manufacturing jobs by 2033, according to Deloitte and the Manufacturing Institute, younger workers have largely turned away from the career path. Gen Z is avoiding factory jobs, citing low wages, according to a 2023 Soter Analytics study. U.S. manufacturing jobs average $25 per hour, about $51,890 annually, falling short of the average American salary of $66,600. While Gen Z enrollment in trade schools is rising, factory positions remain unpopular.

Farley Says Governments Must Invest in Trade Schools and Skilled Trades

“Our governments have to get really serious about investing in trade schools and skilled trades,” Farley said at the Aspen Ideas Festival. He pointed to Germany’s apprenticeship model. “You go to Germany, every one of our factory workers has an apprentice starting in junior high school. Every one of those jobs has a person behind it for eight years that is trained.” Farley advocates for young workers to have strong trade experiences to support what he calls the essential economy.

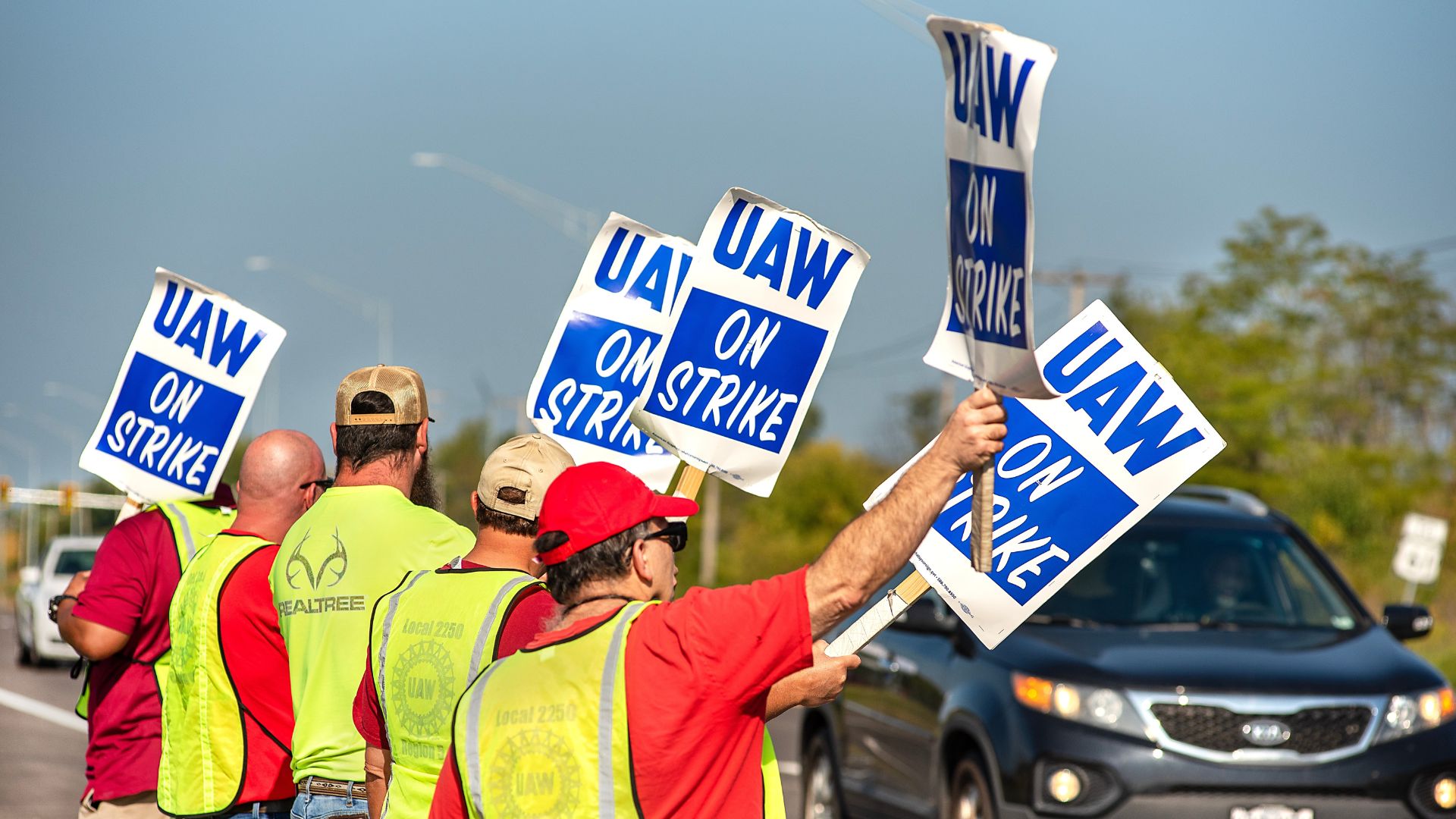

Thousands of Ford Workers Went on Strike in 2023 Over Wages

American carmakers like Ford remain vulnerable to wage disputes. In 2023, thousands of UAW members, including 16,600 Ford employees, went on strike before reaching a contract deal in October. The agreement increased wages and cut the time necessary for temp workers to become full-time. Farley called the strike “completely unnecessary” from management’s perspective, though the worker action demonstrated that compensation concerns had reached a critical point across the automotive industry.

The CEO Says Ford Needs More Help From Others to Solve the Problem

Farley maintained that the responsibility for improving trade workers’ wages extends beyond Ford. “We’re not just going to hope it gets better,” he said. “We have the resources, and we have the know-how, after 120 years, to solve these problems, but we need more help from others.” The CEO’s comments reflect challenges facing American manufacturing as companies work to attract younger workers while maintaining profitability, a balance Farley suggests requires broader industry and government support.

Young Workers Are Forcing Manufacturing to Face Its Future

Ford’s hiring crisis reflects broader challenges across American manufacturing. As young workers choose multiple lower-paying jobs or avoid factories despite higher wages being offered for some positions, companies are confronting a generational shift in career preferences. The disconnect between millions of projected manufacturing jobs and worker interest mirrors the same wage problem Henry Ford addressed in 1914, suggesting compensation remains the key to attracting the next generation of factory workers.